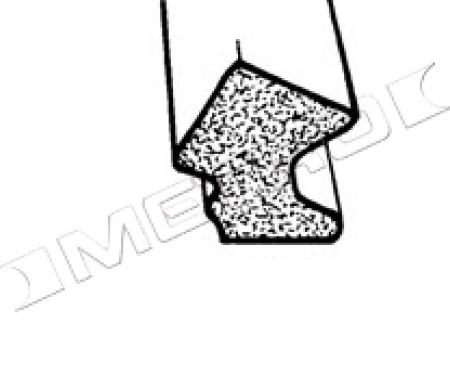

Precision Universal Bulb Seal with rubber covered wire core push-on u-channel UWS 162-25

- Rubber-covered wire core for strong grip and secure push-on attachment.

- U-channel design fits over edges to seal doors, trunks, hoods, glass channels, and trim.

- Reduces wind noise and vibration while preventing moisture intrusion and edge damage.

- Resistant to UV, ozone, and temperature cycling for long-term durability.

- Easy to cut and install — press-on fit with optional adhesive for permanent applications.

- Ideal for restoration, replacement, and general vehicle maintenance.

- Difficulty: 2/5

- Estimated time: 15-30 minutes (per panel, depending on length)

- Measuring tape

- Marker or grease pencil

- Sharp scissors, utility knife, or hacksaw (for core cutting)

- Soapy water or rubber-safe lubricant

- Clean rag and isopropyl alcohol

- Rubber mallet or block (optional)

- Adhesive or seam sealer (optional for permanent hold)

- Measure the length of the edge or channel to be sealed and add a small allowance for trimming or joining.

- Clean the mounting surface thoroughly with isopropyl alcohol and a rag; remove rust, old adhesive, and dirt.

- Cut the bulb seal to length with sharp scissors, a utility knife, or by sawing the internal wire core; protect the rubber edge while cutting.

- Dry-fit the seal along the edge to confirm orientation and length. If joining two pieces, plan a butt or miter joint and trim accordingly.

- Apply a small amount of soapy water or rubber-safe lubricant to the U-channel to ease installation (avoid petroleum-based products).

- Press the seal firmly onto the edge, working along its length. Use a rubber mallet or wooden block to seat the wire core fully into the channel if needed.

- Trim any excess material and finish joints; for a more permanent or water-tight installation, apply an appropriate adhesive or seam sealer at the ends and joints.

- Inspect the installed seal for gaps, secure fit, and proper compression; adjust or re-seat as necessary.

Since 1986 Precision Replacement Parts has been a trusted name in the Automotive Glass Industry.

Our knowledge and experience in manufacturing millions of extruded and molded EPDM Rubber, PVC and HDPE based plastics, and various stamped and extruded metal products for the classic and late model industries has allowed Precision to expand our services into multiple product markets.

Along with our own USA based production facility, Precision also partners with 25 different manufactures worldwide with a reputation as a global leader supplying OEM and replacement products to a number of different industries. Our partnerships along with our own in-house manufacturing and fabrication capability gives Precision a unique position in helping to meet the expanding needs of customers everywhere, providing them with a sustained competitive advantage.

Specifications:

| Part Type | Universal Adhesive Molding |

| Proposition 65 | www.P65Warnings.ca.gov |

| Warranty | Lifetime on Defects TX |