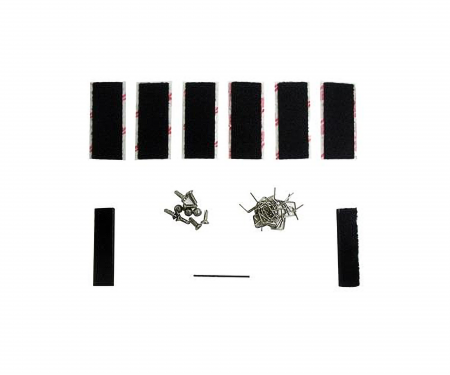

Precision 1969-1975 Chevrolet Corvette Beltline Molding Kit, Left and Right Hand, 4 Piece Kit WFK 1611 69

- Fits 1969–1975 Chevrolet Corvette (left & right; 4-piece beltline molding kit).

- Precision-fit replacement moldings restore the original factory beltline appearance.

- High-quality, corrosion-resistant finish resists rust and weathering for long-lasting durability.

- Protects door edges and paintwork from chips, abrasion and water intrusion.

- Designed for easy installation with factory-style clips and mounting points for a secure fit.

- Ideal for restorations or routine maintenance to return the vehicle to showroom condition.

- Difficulty: 2/5

- Estimated time: 30-60 minutes

- Phillips and flathead screwdrivers

- Trim removal tool or panel puller

- Isopropyl alcohol and clean cloths

- Masking tape

- Small pliers

- Replacement clips or adhesive (if required)

- Prepare the area: park vehicle on a level surface and clean the beltline area thoroughly with isopropyl alcohol to remove wax, grease and debris.

- Remove old molding: carefully pry off the existing molding using a trim removal tool or flathead screwdriver, taking care not to damage paint or sheet metal. Remove and retain any reusable clips or discard damaged clips.

- Inspect and repair mounting points: check clip holes and mounting surfaces for rust or damage. Replace any broken clips or lightly sand and touch up paint where needed.

- Test-fit new pieces: position each molding piece along the beltline to verify orientation (left/right, front/rear) and fit. Use masking tape to hold pieces temporarily if needed.

- Install clips or hardware: attach supplied or replacement clips to the molding or vehicle mounting points per original configuration. If adhesive is used, apply according to adhesive instructions and allow tack time.

- Secure molding in place: align the molding with the beltline and press firmly so clips engage, or fasten with screws/studs if applicable. Work along the length to ensure even seating and avoid bending the molding.

- Final cleanup and inspection: remove masking tape, wipe the molding and adjacent paint with a clean cloth, and inspect for gaps or loose sections. Make minor adjustments to ensure a snug, continuous fit.

- Allow any adhesives to cure: if adhesive was used, follow the manufacturer’s cure time before exposing the vehicle to water or driving at high speeds.

Since 1986 Precision Replacement Parts has been a trusted name in the Automotive Glass Industry.

Our knowledge and experience in manufacturing millions of extruded and molded EPDM Rubber, PVC and HDPE based plastics, and various stamped and extruded metal products for the classic and late model industries has allowed Precision to expand our services into multiple product markets.

Along with our own USA based production facility, Precision also partners with 25 different manufactures worldwide with a reputation as a global leader supplying OEM and replacement products to a number of different industries. Our partnerships along with our own in-house manufacturing and fabrication capability gives Precision a unique position in helping to meet the expanding needs of customers everywhere, providing them with a sustained competitive advantage.

Vehicle Fitment:

| Make | Model | Years |

| Chevrolet | Corvette | 1969 - 1975 |

Specifications:

| Part Type | Door Window Belt Weatherstrip |

| Proposition 65 | www.P65Warnings.ca.gov |

| Warranty | Lifetime on Defects TX |