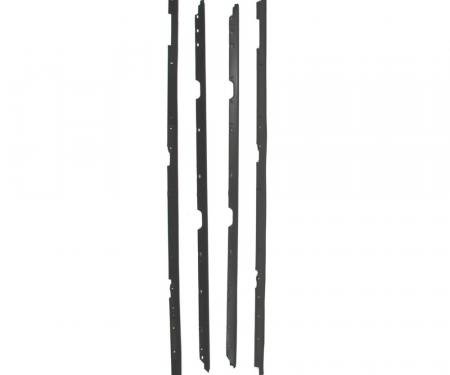

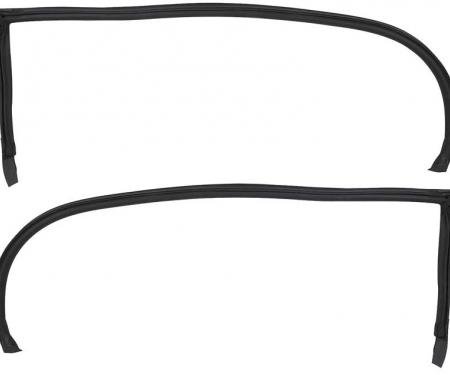

Precision Beltline Molding, Left Hand Outer WFL 1410 82

- Direct replacement left-hand outer beltline molding for restoration and repair.

- Durable, corrosion-resistant metal construction with a factory-style finish.

- Secures the window channel and helps reduce water intrusion and wind noise.

- Designed to restore exterior appearance and protect door edges from damage.

- Straightforward installation — compatible with clip- or screw-style retainers.

- Ideal for restoration, maintenance, and collision repair applications.

- Difficulty: 2/5

- Estimated time: 30-60 minutes

- Trim removal tool or flat pry tool

- Phillips and flathead screwdrivers

- Socket set or nut driver (if fasteners present)

- Clean cloth and isopropyl alcohol

- Masking tape

- Rubber mallet (optional)

- Replacement clips or fasteners (if required)

- Heat gun or hair dryer (optional, for adhesive softening)

- Park vehicle on a level surface and lower the window (if applicable) to access the beltline area.

- Protect the surrounding paint with masking tape along the edge of the door or window opening.

- Carefully remove the old molding: pry out retaining clips or remove screws/fasteners. Use a trim tool to avoid scratching paint.

- Clean the mounting surface thoroughly with isopropyl alcohol to remove old adhesive, dirt, and grease. Allow to dry.

- If the new molding uses adhesive backing, warm the adhesive lightly with a heat gun or hair dryer for better adhesion.

- Test-fit the new molding along the beltline to confirm alignment and orientation before final installation.

- Starting at one end, align the molding and press it into place, engaging clips or fasteners as required. For clip-style parts, push firmly until clips snap into position.

- If screws or bolts are required, install them snugly but avoid overtightening which can warp the molding.

- Trim any excess material if necessary and gently tap areas with a rubber mallet to ensure a uniform seat.

- Inspect the installed molding for gaps, secure fit, and finish. Reinstall any removed interior trim and clean the area.

Since 1986 Precision Replacement Parts has been a trusted name in the Automotive Glass Industry.

Our knowledge and experience in manufacturing millions of extruded and molded EPDM Rubber, PVC and HDPE based plastics, and various stamped and extruded metal products for the classic and late model industries has allowed Precision to expand our services into multiple product markets.

Along with our own USA based production facility, Precision also partners with 25 different manufactures worldwide with a reputation as a global leader supplying OEM and replacement products to a number of different industries. Our partnerships along with our own in-house manufacturing and fabrication capability gives Precision a unique position in helping to meet the expanding needs of customers everywhere, providing them with a sustained competitive advantage.

Vehicle Fitment:

| Make | Model | Years |

| Chevrolet | Camaro | 1982 - 1992 |

| Pontiac | Firebird | 1982 - 1992 |

Specifications:

| Part Type | Door Window Belt Weatherstrip |

| Proposition 65 | www.P65Warnings.ca.gov |

| Warranty | Lifetime on Defects TX |