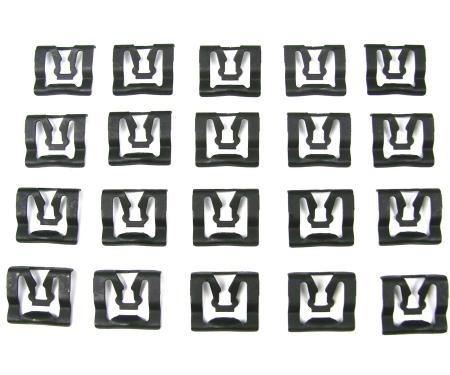

Precision Pop Rivet 11621

- Universal fit for a wide range of vehicles and general-purpose fastening applications

- Made from corrosion-resistant materials for long-term durability

- Blind/pop rivet design allows installation from one side where rear access is restricted

- Provides secure, vibration-resistant fastening for trim, panels, and interior components

- Quick and easy installation with a standard pop rivet gun — great for restoration and repair

- Consistent clamp force helps maintain alignment and prevents loosening over time

- Difficulty: 1/5

- Estimated time: 10–30 minutes depending on quantity and preparation

- Pop rivet gun (hand or pneumatic)

- Electric drill

- Drill bits sized to rivet body diameter

- Center punch or awl

- Deburring tool or file

- Measuring tape or ruler

- Safety glasses and gloves

- Select the correct rivet diameter and length for the combined thickness of the materials being joined.

- Mark the hole location and, if needed, use a center punch to prevent the drill bit from wandering.

- Drill a hole through both materials using a drill bit matched to the rivet body diameter; avoid an oversized hole.

- Deburr the hole edges on both sides to ensure a flush, uniform seating surface.

- Insert the rivet body through the aligned holes so the head sits flush against the outer surface.

- Place the rivet mandrel into the rivet gun, then squeeze the gun handles (or actuate the tool) until the mandrel snaps off and the rivet sets.

- Inspect the installed rivet for a proper bulbed formation on the blind side and a flush head on the exterior.

- Trim or file any sharp edges if needed and test the joint for secure alignment and vibration resistance.

Since 1986 Precision Replacement Parts has been a trusted name in the Automotive Glass Industry.

Our knowledge and experience in manufacturing millions of extruded and molded EPDM Rubber, PVC and HDPE based plastics, and various stamped and extruded metal products for the classic and late model industries has allowed Precision to expand our services into multiple product markets.

Along with our own USA based production facility, Precision also partners with 25 different manufactures worldwide with a reputation as a global leader supplying OEM and replacement products to a number of different industries. Our partnerships along with our own in-house manufacturing and fabrication capability gives Precision a unique position in helping to meet the expanding needs of customers everywhere, providing them with a sustained competitive advantage.

Specifications:

| Part Type | Molding Clip |

| Proposition 65 | www.P65Warnings.ca.gov |

| Warranty | Lifetime on Defects TX |