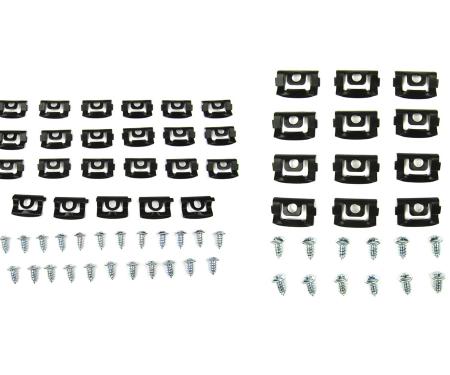

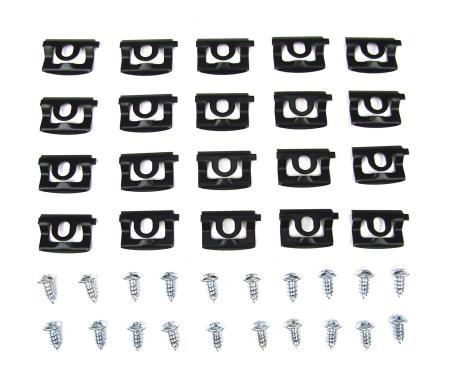

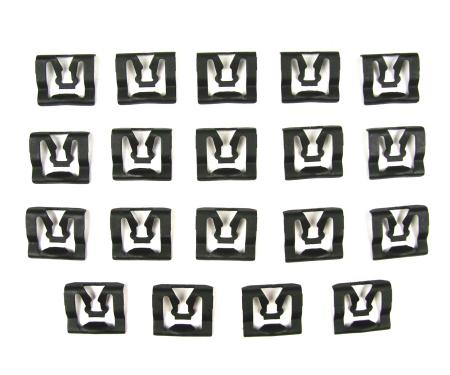

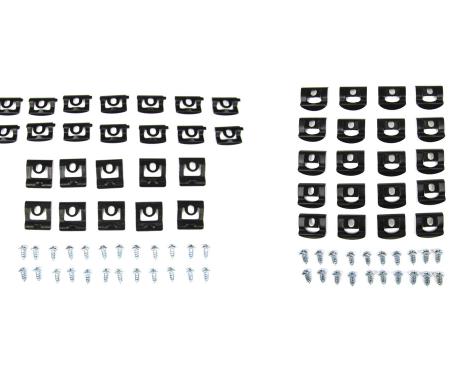

Precision Self Tapping Screw 9399 004

- Heat-treated steel core with a corrosion-resistant finish for long-lasting performance.

- Self-tapping thread design forms secure threads in metal, plastic, and fiberglass substrates.

- Used to fasten trim, interior panels, brackets, and light sheet-metal assemblies.

- Installs with a standard driver or drill/driver—no nut required for most applications.

- Vibration-resistant hold helps prevent loosening in automotive and restoration projects.

- Ideal for restoration, maintenance, and replacement of factory fasteners.

- Difficulty: 1/5

- Estimated time: 1–5 minutes per screw (15–60 minutes for a small panel or trim job)

- Appropriate screwdriver or drill/driver with compatible bit

- Center punch (optional, for precise start)

- Pilot drill bit (optional for hard substrates)

- Torque driver or torque-limited drill (optional)

- Safety glasses

- Confirm screw size is correct for the hole thickness and substrate.

- If working with hard metal or for precise alignment, mark the location and use a center punch to prevent wandering.

- For very hard substrates, drill a small pilot hole sized per material thickness; otherwise, self-tapping screws often can form threads without a pilot.

- Align the parts to be fastened and start the screw by hand to ensure correct engagement.

- Using a screwdriver or a drill/driver on low speed, drive the screw straight into the material. Maintain steady pressure and keep the driver aligned with the screw axis.

- Avoid over-torquing—stop once the head is seated flush or at the desired engagement to prevent stripping the formed thread or breaking the screw.

- If reinstalling in treated or corroded holes, clean the hole and consider a small amount of anti-seize or thread lubricant to aid future removal.

- Inspect the joint for proper clamping and re-check fastener tightness after initial use or vibration exposure.

Since 1986 Precision Replacement Parts has been a trusted name in the Automotive Glass Industry.

Our knowledge and experience in manufacturing millions of extruded and molded EPDM Rubber, PVC and HDPE based plastics, and various stamped and extruded metal products for the classic and late model industries has allowed Precision to expand our services into multiple product markets.

Along with our own USA based production facility, Precision also partners with 25 different manufactures worldwide with a reputation as a global leader supplying OEM and replacement products to a number of different industries. Our partnerships along with our own in-house manufacturing and fabrication capability gives Precision a unique position in helping to meet the expanding needs of customers everywhere, providing them with a sustained competitive advantage.

Specifications:

| Part Type | Screw |

| Proposition 65 | www.P65Warnings.ca.gov |

| Warranty | Lifetime on Defects TX |